Using INA226AIDGSR for Efficient Current Monitoring in Remote Sensors

The INA226AIDGSR is an excellent choice for current and power monitoring in remote sensor networks. With an impressive accuracy of ±0.02% and a low input bias current of just 10μA, it ensures energy efficiency and precise measurements. Operating reliably across a wide temperature range of -40°C to 125°C, it is suitable for various environmental conditions. The device functions with a supply voltage between 2.7V and 5.5V while consuming only 330μA of power, making it ideal for low-power applications. If you're wondering how to implement INA226AIDGSR current monitoring in a remote sensor network.ti, this device can significantly enhance sensor performance, optimize energy usage, and extend operational lifespan. Explore the potential of the INA226AIDGSR to elevate your system's efficiency.

Key Takeaways

The INA226AIDGSR is very accurate at ±0.02%, giving dependable current readings for your sensor projects.

It uses very little power, only 330μA, which is great for devices that run on batteries and helps them last longer.

This sensor works well in very hot or cold places, from -40°C to 125°C, so it can handle tough environments.

By using the INA226AIDGSR, you can save energy in remote sensor systems because it tracks power in real time.

Picking the right shunt resistor is important for good current readings; make sure it fits your circuit's needs.

Understanding the INA226AIDGSR

Features and Specifications

The INA226AIDGSR has many features for current monitoring. It is very accurate with a precision of ±0.02%. Its input bias current is only 10μA, saving energy. This device works in temperatures from -40°C to 125°C, so it fits many environments. It uses a supply voltage of 2.7V to 5.5V and needs just 330μA of power, making it great for low-power uses.

Here’s a simple list of its main specifications:

Feature | Specification |

|---|---|

High accuracy | ±0.02% |

Common mode rejection ratio | 140 dB |

Input bias current | 10μA |

Input offset voltage | 2.5μV |

Operating temperature range | -40°C to 125°C |

Supply voltage range | 2.7V to 5.5V |

Nominal supply current | 330μA |

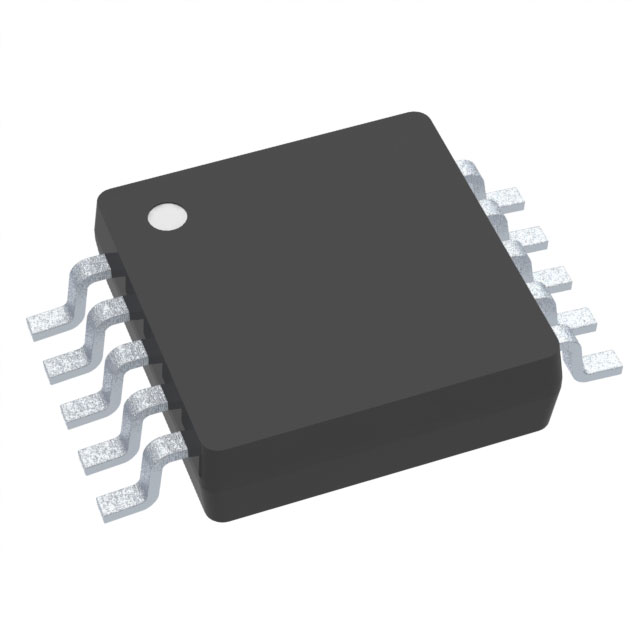

Package options | 10-TFSOP, 10-MSOP |

The INA226AIDGSR checks voltage drop across a shunt resistor. Using Ohm’s law (I = V/R), it calculates current. It can measure up to 81.92mV with a resolution of 2.5µV, giving accurate results. It also supports I2C and SMBus for easy digital communication.

Advantages for Remote Sensor Networks

The INA226AIDGSR is great for remote sensors because it is efficient and reliable. Its low input bias current and high accuracy save battery power. It works well in very hot or cold places, ensuring steady performance. With a 140 dB common mode rejection ratio, it reduces interference for clear readings.

This device also helps manage power by showing current, voltage, and power data. You can track energy use in real time to improve sensor performance. Its small size and low power needs make it perfect for tight spaces.

Why Choose the INA226 DC Current Sensor?

The INA226 DC current sensor is precise and flexible. It measures bus voltages from 0V to 36V and works for both high-side and low-side sensing. It has a maximum gain error of 0.1% and an offset of 10μV, ensuring accurate readings. Its RoHS3 compliance and small 10-pin design make it eco-friendly and easy to use.

By picking the INA226 DC current sensor, you get advanced features like real-time power tracking and digital communication. These tools help improve the efficiency and lifespan of remote sensors. Whether for IoT or environmental projects, this sensor gives the accuracy and dependability you need.

Hardware Setup for INA226AIDGSR

Pinout and Connections

Setting up the INA226AIDGSR starts with knowing its pins. It has a small 10-pin design, perfect for tight spaces. Important pins include VIN+ and VIN- for the shunt resistor, SCL and SDA for I2C communication, and VCC for power. Connect the GND pin to ground to complete the circuit.

Place the shunt resistor between the VIN+ and VIN- pins. This lets the device measure voltage drop and calculate current. Use SCL and SDA pins to connect to a microcontroller like Arduino for data transfer. Correct wiring ensures accurate readings and smooth operation.

Picking the Right Current Sensing Resistor

Choosing the right resistor is key for good measurements. Follow these steps to pick the best one:

Understand Circuit Needs: Check if the current is DC or AC. Know the maximum current and voltage levels. Decide how precise your readings should be.

Find Resistor Value: Use V = I x R to calculate resistance. Pick a value that keeps voltage drop low but still detects current.

Check Power Ratings: Use P = I²R to find power dissipation. Choose a resistor with extra power capacity, about 25% to 50% more than needed.

Think About Size and Heat: Make sure the resistor fits your design and handles heat well.

The right resistor helps the INA226AIDGSR measure current better, boosting your sensor network's performance.

Circuit Diagram for Sensor Integration

Adding the INA226AIDGSR to a sensor circuit needs careful planning. Below is a typical setup:

Component | Description |

|---|---|

INA226AIDGSR | Example Circuit for remote sensors |

The INA226 module works with microcontrollers like Arduino. It includes the INA226 chip, resistors, and capacitors to reduce noise and improve signals. Connect the module using the pinout explained earlier. This setup ensures accurate current sensing and easy integration into your sensor system.

Software Integration for Current Monitoring

Setting Up I2C Communication

To use the INA226AIDGSR, you need to set up I2C communication. I2C is a simple two-wire system using SDA (data) and SCL (clock). Connect the INA226AIDGSR's SDA and SCL pins to your microcontroller. Also, connect the VCC pin for power and GND pin for ground.

After connecting the hardware, set the INA226AIDGSR's I2C address. This address helps the microcontroller find and talk to the sensor. Most sensors have a default address, but you can change it by adjusting the address pins. Use your microcontroller's I2C library to start communication. Scan for the device to confirm the connection works.

Configuring Registers for Accurate Measurements

The INA226AIDGSR has registers that control how it works and stores data. To measure current correctly, you must set these registers. First, configure the calibration register. This step ensures the sensor calculates current and power based on your shunt resistor.

Then, set the configuration register to choose averaging, conversion time, and measurement mode. For example, continuous mode lets the sensor measure without stopping. Use I2C commands from your microcontroller to write these settings. Check the datasheet for the right register addresses and values.

Using Libraries and Code Examples for INA226AIDGSR

Libraries make it easier to use the INA226AIDGSR in your project. A helpful library is available from Wollewald. It includes functions to set up the sensor and read current, voltage, and power. The library also has seven examples showing features like continuous mode and averaging.

Here’s a simple code example:

#include <INA226.h>

INA226 ina226;

void setup() {

Wire.begin();

ina226.begin();

ina226.configure(INA226_AVERAGES_16, INA226_BUS_CONV_TIME_140US, INA226_SHUNT_CONV_TIME_140US, INA226_MODE_SHUNT_BUS_CONT);

}

void loop() {

float current = ina226.readCurrent();

Serial.println(current);

delay(1000);

}

This code starts the INA226AIDGSR, sets its registers, and reads current in a loop. Using libraries and examples saves time and reduces mistakes.

How to Use INA226AIDGSR for Current Monitoring in Remote Sensors

Easy Steps to Set It Up

Follow these steps to add the INA226AIDGSR to your sensor system:

Set Up Hardware: Attach the INA226AIDGSR to your microcontroller. Connect the VIN+ and VIN- pins to the shunt resistor. Use SDA and SCL pins for I2C communication. Link the GND pin to ground.

Pick a Shunt Resistor: Choose a resistor that fits your current needs. Use Ohm’s law to find the right value. Make sure it can handle the heat and power.

Program the Software: Enable I2C on your microcontroller. Use libraries to make coding easier. Adjust the INA226AIDGSR settings for accurate readings.

Test Everything: Check all connections. Run a simple program to read current. Change settings if needed for better results.

These steps make it simple to monitor current in your sensor system.

Writing Code for Remote Sensors

When coding for remote sensors, use helpful libraries. For example, the INA226 library has tools to set up the sensor. It also reads current, voltage, and power data. Change settings like averaging or timing to match your project.

Here are some useful coding resources:

Resource | What It Offers |

|---|---|

Learn to analyze maps and data using R. | |

Coding for Reproducible Research | Improve coding skills with lessons and quizzes in R. |

NEON Data Institute 2018 | Learn Python for remote sensing and machine learning. |

Orfeo ToolBox | Free tools for editing remote sensing images with many applications. |

These tools help you write better code for remote sensors.

Solving Common Problems

Adding current monitoring to sensors can be tricky. Here are common problems and how to fix them:

Noisy Signals: Add capacitors to reduce noise. The INA226AIDGSR also blocks interference with its high rejection ratio.

Wrong Readings: Check the resistor value. Make sure the sensor is calibrated correctly.

Connection Issues: Confirm I2C wires and address settings. Use a logic analyzer to find problems.

Power Limits: Adjust settings to save energy. Use continuous mode only when needed.

Fixing these problems ensures your sensor system works well and lasts longer.

Testing and Results

Checking the Hardware Setup

Before using the sensor, make sure the hardware works. Look at all the connections carefully. The shunt resistor should be firmly placed between the VIN+ and VIN- pins. Ensure the SDA and SCL pins are connected to the microcontroller for I2C communication. Check that the power supply matches the INA226AIDGSR voltage range.

After checking the connections, upload a simple test program to your microcontroller. This program should read current and power values from the INA226AIDGSR. Display these readings on a serial monitor. If the numbers seem wrong or unstable, check the wiring again. Also, confirm the I2C address matches the sensor's setup.

Understanding Current and Power Data

Reading data from the INA226AIDGSR helps improve your system. The sensor gives accurate current, voltage, and power measurements. Use this information to study energy use and find ways to save power in your sensor network.

Here’s how to use the data:

Analysis Type | Purpose |

|---|---|

Shows how active, reactive, and apparent power relate. | |

Harmonic Analysis | Finds how nonlinear loads affect current and voltage. |

Short Circuit Analysis | Explains circuit behavior and component limits during faults. |

Coordination Analysis | Helps design overcurrent protection by studying device features. |

These analyses help you understand your system better and make it more efficient.

Fixing Problems and Improving Performance

If something goes wrong, follow a step-by-step process to fix it. Start by checking past records and documents. Watch how the sensor behaves and test ideas to find the problem. Common issues include noisy signals, wrong readings, or bad connections.

To make the system work better, try these maintenance tips:

Keep Track of Sensors: Record sensor details and maintenance history.

Regular Inspections: Check sensors often to avoid problems.

Predict Failures: Use data to guess when repairs are needed.

Fix When Needed: Only repair sensors if their performance drops.

Also, solve common problems like dirt, lack of lubrication, or overheating. For example:

Description | |

|---|---|

Dirt/contamination | Can cause sensor errors and damage. |

Poor lubrication | Leads to heat and faster wear. |

Overheating | Harms electrical parts and may cause failure. |

By fixing these issues early, you can keep your sensor network running smoothly and for a longer time.

Applications of INA226 DC Current Sensor in Remote Sensor Networks

How It Helps in IoT and Environmental Monitoring

The INA226 DC current sensor is important for IoT and environmental tasks. In IoT, it helps manage energy in devices like smart meters and wearables. It gives accurate power readings, making devices work better. For example, in a smart home, it tracks appliance energy use. This helps save money and reduce waste.

In environmental monitoring, it supports systems checking air, water, and weather. These systems often use batteries or solar power. The INA226 saves energy, helping these systems last longer. It also works in extreme weather, from hot deserts to freezing poles.

Why Use INA226AIDGSR in Real-Life Situations

The INA226AIDGSR has many real-world benefits. Its accuracy gives reliable data, useful in fields like farming and healthcare. For example, in farming, it tracks irrigation power use. This helps save water and improve crop growth.

Its low power use is great for battery devices, especially in remote areas. Changing batteries in such places is hard. Its small size fits tiny gadgets, making it flexible for many uses. Whether for wearables or big machines, the INA226 works well.

Future of Current Monitoring for Remote Sensors

Current monitoring is improving with new technology. Sensors are becoming smaller, smarter, and more efficient. They help solve big problems like energy waste and climate change. AI is making sensors better by analyzing data instantly. This improves their performance.

The need for sensors in IoT and healthcare is growing fast. Experts predict the sensor market will reach $253 billion by 2035. New tech like 6G and tiny sensors will drive this growth.

Year | Market Size (US$) | Key Trends and Tech |

|---|---|---|

2025 | N/A | Advanced sensors widely used |

2035 | 253B | Growth from AI, IoT, and 6G tech |

These trends show why advanced sensors like the INA226AIDGSR are important. Using them keeps your systems modern and competitive.

The INA226AIDGSR is a great tool for checking current in remote sensors. It is very accurate, uses little power, and works in many temperatures. This makes it a good choice for different projects. Its precise readings and real-time power tracking help save energy and make systems last longer.

Tip: Use the INA226AIDGSR to improve your IoT or environmental projects. Its smart features make it reliable and efficient.

Try this sensor to make your remote sensor projects even better!

FAQ

1. How does the INA226AIDGSR measure current?

The INA226AIDGSR checks current by measuring voltage drop on a shunt resistor. It uses Ohm’s Law (I = V/R) to find the current. This method gives accurate results, perfect for tracking energy in remote sensors.

2. Can the INA226AIDGSR work in extreme temperatures?

Yes, the INA226AIDGSR works well in temperatures from -40°C to 125°C. This wide range makes it great for tough environments, like outdoor areas, ensuring steady performance in remote sensors.

3. What microcontrollers are compatible with the INA226AIDGSR?

The INA226AIDGSR uses I2C communication, so it works with Arduino, Raspberry Pi, and ESP32. You can easily connect it to your projects using I2C libraries and standard wiring.

4. Why is choosing the right shunt resistor important?

The shunt resistor affects how accurate the current readings are. Picking the right value balances low voltage drop with precise measurements. Always calculate the resistor based on your circuit’s needs.

5. Is the INA226AIDGSR suitable for battery-powered devices?

Yes! The INA226AIDGSR uses only 330μA of power, making it great for battery devices. Its low power use helps devices in remote sensors last longer.

Tip: Double-check your hardware and software setup to get the best performance from the INA226AIDGSR in your projects.