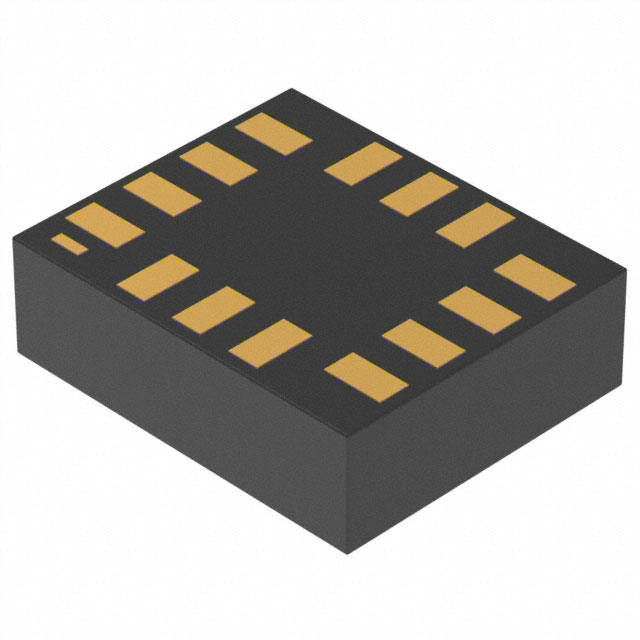

Sensor integration application of ICM-42688-P chip in light UAV

The sensor integration application of ICM-42688-P chip in light UAV significantly enhances their performance. By incorporating the ICM-42688-P, these small drones achieve precise motion tracking and improved stability. This chip simplifies the process of integrating sensors into light UAVs, which is crucial for advancing drone designs. To maximize its potential, follow three key steps: hardware setup, software calibration, and performance optimization. The ICM-42688-P’s advanced features enhance drone control, making it ideal for aerial photography. It ensures smooth and reliable flights, even under challenging weather conditions.

Key Takeaways

The ICM-42688-P chip helps small drones track movement better. It also makes them steadier, which is great for taking pictures from the air.

Setting up the hardware right is very important. This includes proper wiring and a steady power source for the chip to work well in drones.

Calibrating the ICM-42688-P chip is needed for correct motion data. Do this again after crashes or big temperature changes.

Using vibration blockers and mounting the chip correctly makes it work more accurately during flights.

Cleaning and checking connections often keeps the ICM-42688-P chip working properly for a long time.

Overview of the ICM-42688-P chip

Features of the ICM-42688-P

The ICM-42688-P chip is a powerful 6-axis IMU. It combines a gyroscope and an accelerometer for better performance. The gyroscope has low noise at 2.8 mdps/√Hz. The accelerometer also has low noise at 70 μg/√Hz. It supports different ranges, like ±2000 dps for the gyroscope. The accelerometer can measure up to ±16 g. This makes it useful for many tasks. Its low-noise mode uses only 0.88 mA, saving energy. The chip also has digital filters you can program. It includes features like tilt detection and wake-on-motion.

Specification | Value |

|---|---|

Gyroscope Noise | 2.8 mdps/√Hz |

Accelerometer Noise | 70 μg/√Hz |

Low-Noise Mode Current Consumption | 0.88 mA |

Gyro Full-Scale Range | ±15.6 to ±2000 dps |

Accelerometer Full-Scale Range | ±2 to ±16 g |

Motion Functions | Pedometer, Tilt Detection, Wake on Motion, etc. |

Suitability for light UAVs

The ICM-42688-P chip works great in small drones. Its small size and low power use are perfect for UAVs. It fits well into platforms like Ardubee for drone studies. The gyroscope and accelerometer help track motion and keep drones steady. This is important for flying and navigation. Its energy-saving design helps drones fly longer. This is useful for lightweight drones used in photography or other tasks.

Role in UAV flight systems

The ICM-42688-P chip is key to drone flight systems. It gives accurate motion data to keep the drone stable. This helps drones adjust to changes in the environment. The chip’s features, like filters and motion detection, improve drone performance. It is great for aerial photography and research. The chip ensures smooth flights, even in tough conditions.

Benefit | Application |

|---|---|

Precision | |

Reliability | Drone stabilization |

Energy Efficiency | Suitable for lightweight drones |

Using the ICM-42688-P chip in small drones improves their performance. It helps with stability and accuracy, making flights smooth and reliable.

Hardware Integration

Wiring and pin connections

Correct wiring is very important for using the ICM-42688-P chip. Connect the chip to the flight controller carefully for good communication. The chip works with SPI or I2C protocols, so pick the one that fits your drone. For SPI, connect SCLK, SDI, SDO, and CS pins to the flight controller. For I2C, use the SDA and SCL pins. Always check the datasheet for the right connections.

Keep wires short to avoid signal problems. Use shielded cables if there’s a lot of electromagnetic interference. Check all connections before turning on the system. Loose or wrong connections can cause errors or damage the chip.

Power supply and voltage requirements

The chip needs a voltage between 1.8V and 3.3V to work. Make sure the flight controller gives steady power in this range. Some controllers have voltage regulators, but check their output first. If not, add an external regulator.

Stable power is key for accurate sensor data. Voltage changes can make the gyroscope and accelerometer less accurate. Add capacitors near the chip to reduce power noise. Also, ensure the power supply can handle the chip’s energy needs, especially in low-noise mode.

Mounting considerations for stability

Mounting the chip properly helps keep the drone stable. Place it near the drone’s center of gravity to reduce vibration effects. Use a strong but light platform to hold the chip.

A four-point mounting system can improve stability. This setup reduces movement and keeps the sensor aligned. Tests show this design makes sensors more accurate during flight. Vibration isolators can also help by reducing motor vibrations. These have been tested to work well in real conditions.

Evidence Type | Description |

|---|---|

VLF EM Sensor Integration | Tests to find noise limits and best mounting setups. |

Four-Point Mounting System | A design to keep the sensor steady and aligned. |

Vibration Analysis | Tests of isolators to ensure accurate sensor readings. |

Follow these steps to set up the ICM-42688-P chip in your drone. Good wiring, steady power, and proper mounting will give accurate tracking and reliable performance. This is very useful for tasks like aerial photography, where precision matters.

Software Configuration

Firmware setup and initialization

To make the ICM-42688-P chip work, set up its firmware. First, check if your flight controller supports the chip. Many modern controllers for small drones have built-in libraries for IMU sensors. Download the latest firmware version that works with your controller. This gives you new features and fixes any bugs.

After updating the firmware, configure the chip by setting its registers. Use the datasheet to find the right register addresses. For example, you can adjust the gyroscope and accelerometer ranges to fit your drone's needs. A simple setup script might look like this:

// Example setup for ICM-42688-P

writeRegister(0x06, 0x01); // Adjust gyroscope range

writeRegister(0x07, 0x03); // Adjust accelerometer range

writeRegister(0x10, 0x00); // Turn on low-noise mode

Next, test the sensor using debugging tools. Check if the gyroscope and accelerometer give correct data. This step ensures the chip is ready for your drone's flight system.

Tip: Save your controller's original firmware before making changes. This way, you can restore it if needed.

Communication protocols: SPI vs. I2C

The ICM-42688-P chip uses two communication methods: SPI and I2C. Choose the one that fits your drone's design and needs. Here's a simple comparison:

Feature | SPI | I2C |

|---|---|---|

Speed | Very fast | Slower |

Communication Mode | Sends and receives at once | Sends or receives, not both |

Real-Time Performance | Uses a separate clock line | Shares a clock line |

Data Integrity | No built-in checks | Has built-in checks |

Noise Immunity | Better in noisy areas | Weaker in noisy areas |

SPI is faster and handles noise better, so it’s good for drones needing quick, stable data. But it uses more pins, which may not suit small controllers. I2C is simpler and uses fewer pins but is slower and less stable in noisy places.

If your drone needs speed and stability, pick SPI. If your design is simple or has limited pins, use I2C. Match your controller to the chosen method. For SPI, connect SCLK, SDI, SDO, and CS pins. For I2C, connect SDA and SCL pins.

Calibration for accurate motion data

Calibration helps the ICM-42688-P chip give accurate motion readings. Start by placing the drone on a flat surface. This helps the chip set a baseline for its sensors. Use your controller's calibration tool to do these steps:

Gyroscope Calibration: Keep the drone still while the tool records the gyroscope's resting data. This removes errors in rotation readings.

Accelerometer Calibration: Move the drone to align each axis with gravity. The tool checks the accelerometer's response for accurate motion tracking.

Temperature Compensation: Some controllers let you calibrate the chip for different temperatures. This helps in changing weather.

Note: Recalibrate the chip after crashes or big temperature changes. This keeps it accurate over time.

Good calibration improves the ICM-42688-P chip's performance in light UAVs. It ensures the sensors give reliable data, which is important for smooth flights and tasks like aerial photography.

Performance Optimization

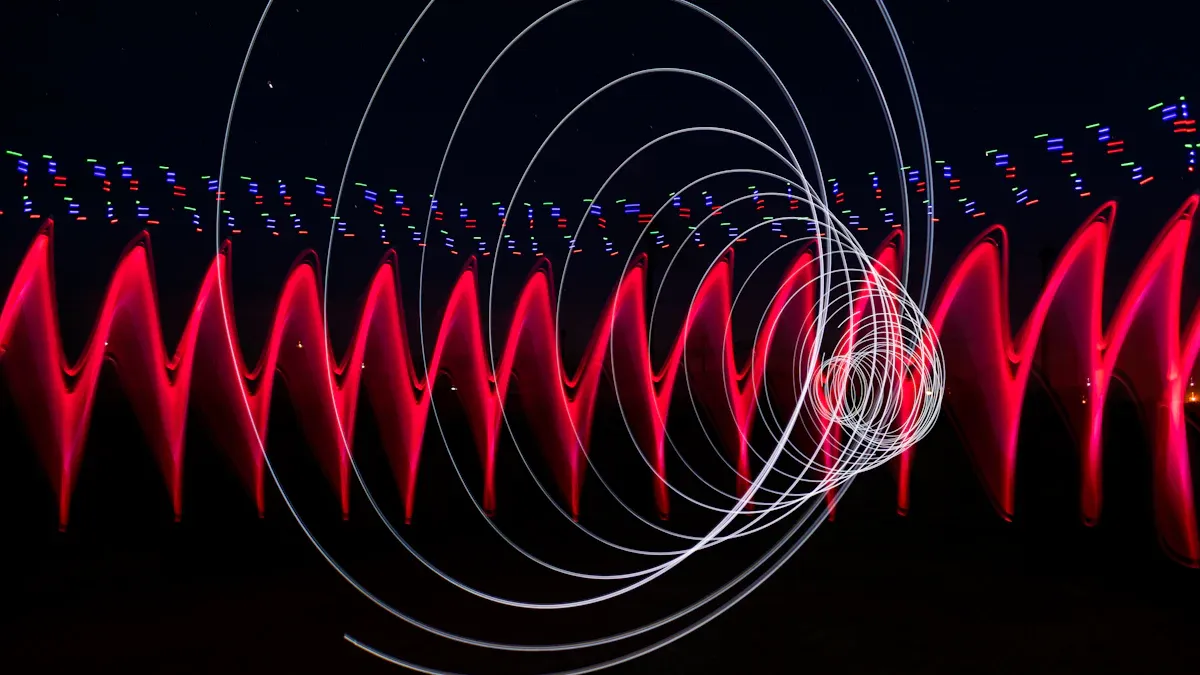

Vibration filtering methods

Filtering vibrations is important for better drone performance. Motor and propeller vibrations can confuse the gyroscope and accelerometer. This causes wrong motion readings. To fix this, use software filters like low-pass filters. You can also add hardware tools like vibration dampeners.

Tests show how vibration filtering helps. For example, flutter analysis shows speed changes from 24 m/s to 34 m/s with extra weight. This proves filters adjust to different conditions. Fiber optic sensors (FOS) also help. They give live data on wing bending, reducing motion errors during flight.

Evidence Description | Findings |

|---|---|

Flutter analysis method sensitivity | Speed changes from 24 m/s to 34 m/s with extra weight. |

Fiber Optic Sensors (FOS) | Live wing data improves wing performance and reduces errors. |

Data fusion techniques for UAVs

Data fusion mixes data from many sensors to improve accuracy. For drones, it combines IMU, GPS, and barometer data. This makes navigation and stability better. Kalman filtering is a common method for this.

Studies prove data fusion works well. The evo tool shows high path accuracy, matching real-world paths. Absolute trajectory error (ATE) stats also show it helps rebuild scenes correctly.

Model | R² Value | RMSE (t ha−1) | RPD | RPIQ |

|---|---|---|---|---|

Cubist | 0.527 - 0.670 | 0.916 | 1.771 | 2.602 |

Ensemble Learning | Up to 0.692 | N/A | N/A | N/A |

Tuning for flight-specific applications

Tuning the flight controller makes drones work better for tasks. PID tuning fixes errors in how the drone rotates. Change proportional, integral, and derivative settings for better control.

Tests for specific tasks also improve sensor use. Adding temperature data makes calibration more accurate. Adjust things like image quality, flight height, and overlap to collect enough data. These changes help drones meet the needs of light UAV tasks.

Tip: Test and recalibrate your flight controller often for best results.

Troubleshooting and Best Practices

Fixing common integration problems

When adding the ICM-42688-P chip to your drone, issues may arise. Wrong wiring often causes errors between the chip and controller. Check all connections to match the chosen protocol, SPI or I2C. Loose wires can stop data flow, so secure them tightly.

Power issues can hurt the chip's performance. Ensure the voltage stays between 1.8V and 3.3V. If power is unstable, place capacitors near the chip to fix it. Poor mounting can also cause wrong sensor readings. Mount the chip near the drone's center and use vibration dampeners to reduce shaking.

Keeping sensor accuracy over time

To keep the ICM-42688-P chip accurate, monitor and calibrate it often. Follow proper installation steps to ensure all drones are set up the same way. Use the settings from the chip's datasheet to avoid overworking the sensors.

Create a routine to check the chip’s performance regularly. Watch the sensor’s status to catch problems early. Keep a record of how the chip works over time. This helps plan maintenance and fix issues before they affect the drone.

Tips for long-term care

To make the ICM-42688-P chip last longer, follow simple care steps. Clean the chip and nearby parts to stop dust from causing problems. Check wires and connectors for damage and replace them if needed.

Recalibrate the chip after crashes or extreme temperature changes. This keeps the gyroscope and accelerometer working correctly. Store the drone in a dry, stable place when not in use. Avoid areas with high humidity or big temperature swings. Update the flight controller firmware often to keep it compatible with the chip and get new features.

Tip: Regular care improves the chip’s performance and makes your drone more reliable.

Adding the ICM-42688-P chip to your small drone needs three steps: setting up hardware, configuring software, and improving performance. These steps help the chip work well, giving accurate motion data and keeping the drone steady. This chip makes drones better for jobs like taking pictures or doing research.

To get the best results, use good wiring, calibrate the chip, and take care of it regularly. These actions will help your drone fly smoothly and work reliably. By following these tips, you can make your drone perform better and last longer.

FAQ

Why is the ICM-42688-P chip good for small drones?

It’s tiny, uses little power, and tracks motion well. These features help drones stay steady and fly smoothly.

How do you pick between SPI and I2C?

SPI sends data faster and handles noise better. It’s great for advanced drones. I2C uses fewer wires and works for simple designs. Choose based on your drone’s needs.

Why does the chip need calibration?

Calibration fixes sensor mistakes for better motion tracking. It helps drones fly steady, especially after crashes or weather changes.

How can you stop vibrations from messing up the chip?

Add dampeners to reduce motor shaking. Use filters to block extra vibrations. Mount the chip near the drone’s center for better accuracy.

What care keeps the chip working well?

Clean it often and check wires for damage. Recalibrate after crashes. Store the drone in a dry place to avoid humidity problems.

See Also

Exploring ASM330LHHTR's Role in Drone Flight Stability

Unveiling STM32L151C8T6A's Dominance in Sensor Innovation

Integrating ADXRS453BRGZ for Accurate Autopilot Functionality

Implementing INA226AIDGSR for Effective Remote Current Monitoring